Custom CBD Packaging Box Manufacturer

With over two decades of expertise in crafting bespoke packaging solutions, our company excels in providing a diverse range of customizable options specifically tailored to meet all your CBD product needs. We offer these personalized solutions at competitive rates, ensuring that your products command attention both on the shelf and in the market.

Table Of Contents For This Page

Each individual section is interactive, allowing to click on it for instantaneous access to the relevant and specific information you are seeking.

What CBD Packaging Boxes Are

CBD packaging boxes, are typically crafted from cardboard, paperboard or corrugated board, serve as specialized containers tailored for the packaging and storing of CBD products. These encompass a range of items such as CBD oils, tinctures, capsules, edibles and other derivatives.

√ Ensure product integrity during storage and transportation.

√ Showcase brand identity and values effectively.

√ Convey vital product details, fostering transparency and trust.

√ Enhance product usability and convenience for consumers.

√ Set the brand apart and foster loyalty, encourage repeat purchases.

Products Suitable for Custom CBD Packaging Boxes

Custom CBD packaging boxes are commonly employed for a range of CBD products, serving to draw consumer attention and set the product apart from competitors.

CBD Oil Bottles

Pre Roll Tubes

Hemp Cigarette

Pre-rolled Cones

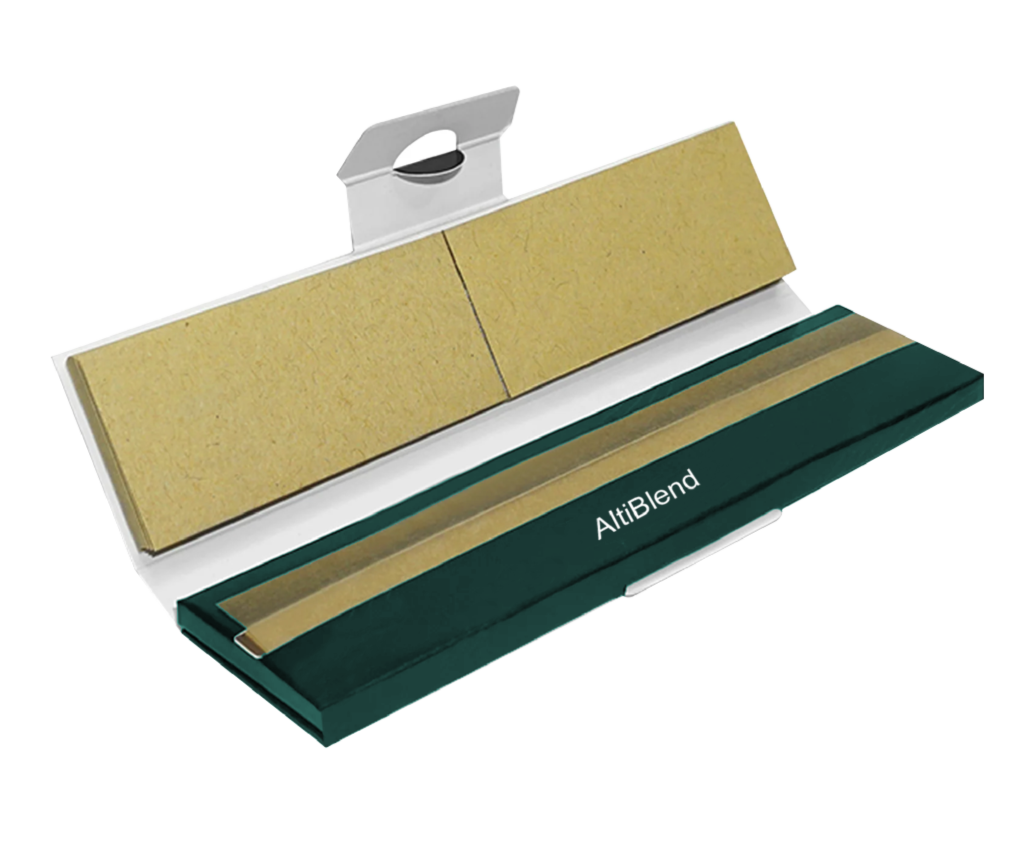

Rolling Papers and Tips

Vape Cartridge

CBD Food

CBD Cosmetic

CBD Medicine

CBD Retail

Hot Selling Types of Custom CBD Packaging Boxes

Eco-friendliness Custom of CBD Packaging Boxes

At SYK Productions, we prioritize sustainability in our packaging solutions. Our boxes are crafted from eco-friendly materials sourced responsibly and are fully recyclable. We employ safe inks and adhesives to ensure both consumer safety and environmental health. With a lightweight yet durable design, our boxes minimize the environmental footprint associated with transportation, demonstrating our dedication to sustainable business practices.

Expanding Customization Horizons of CBD Packaging Boxes

Sustainable Inserts

Paperboard Insert

Corrugated Insert

Blister Insert

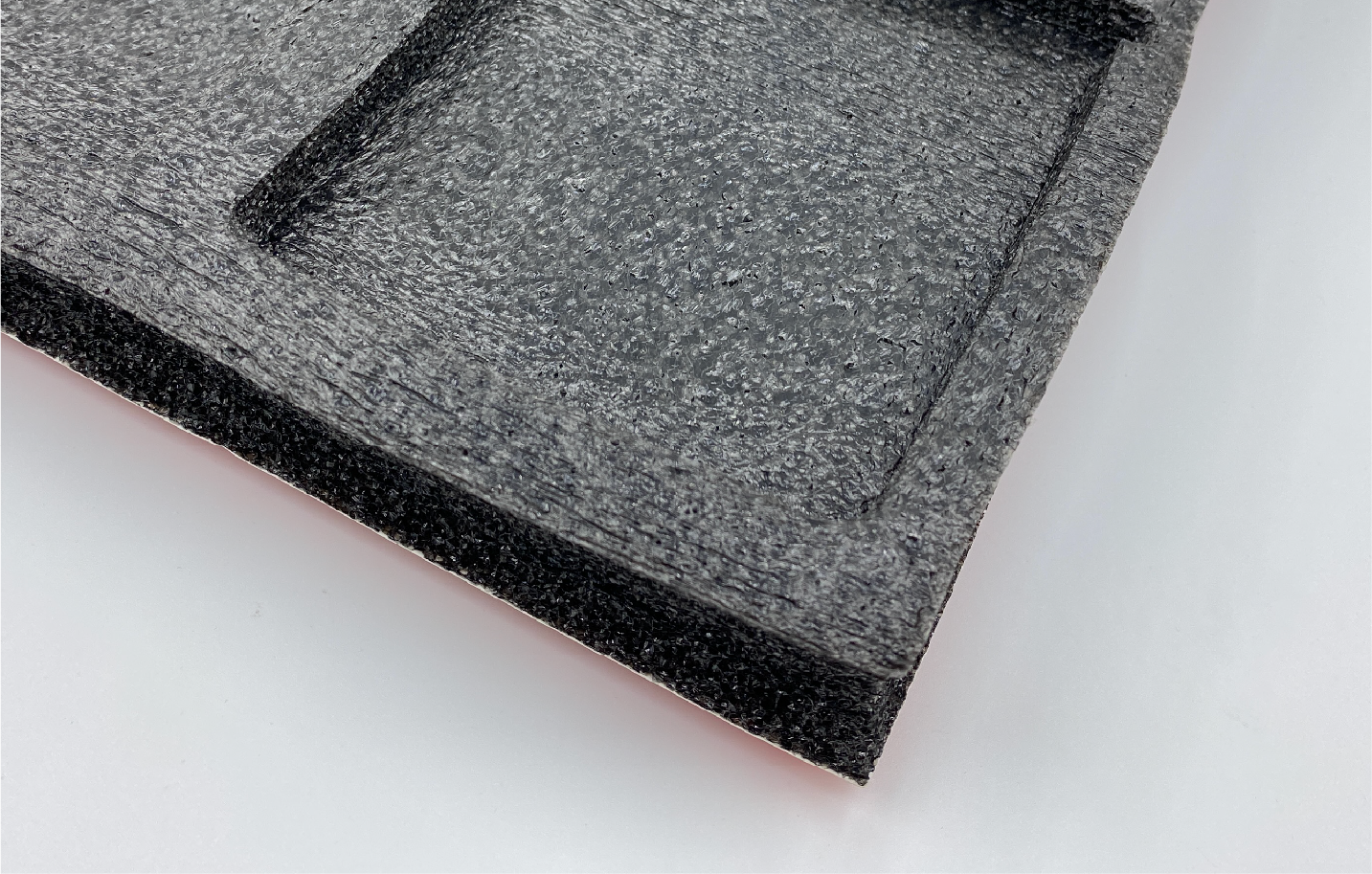

Foam Insert

Pearl Cotton Insert

EVA Foam Inserts

Coating

Gloss Lamination

Matte Lamination

Aqueous Varnishing

How CBD Packaging Boxes Are Made

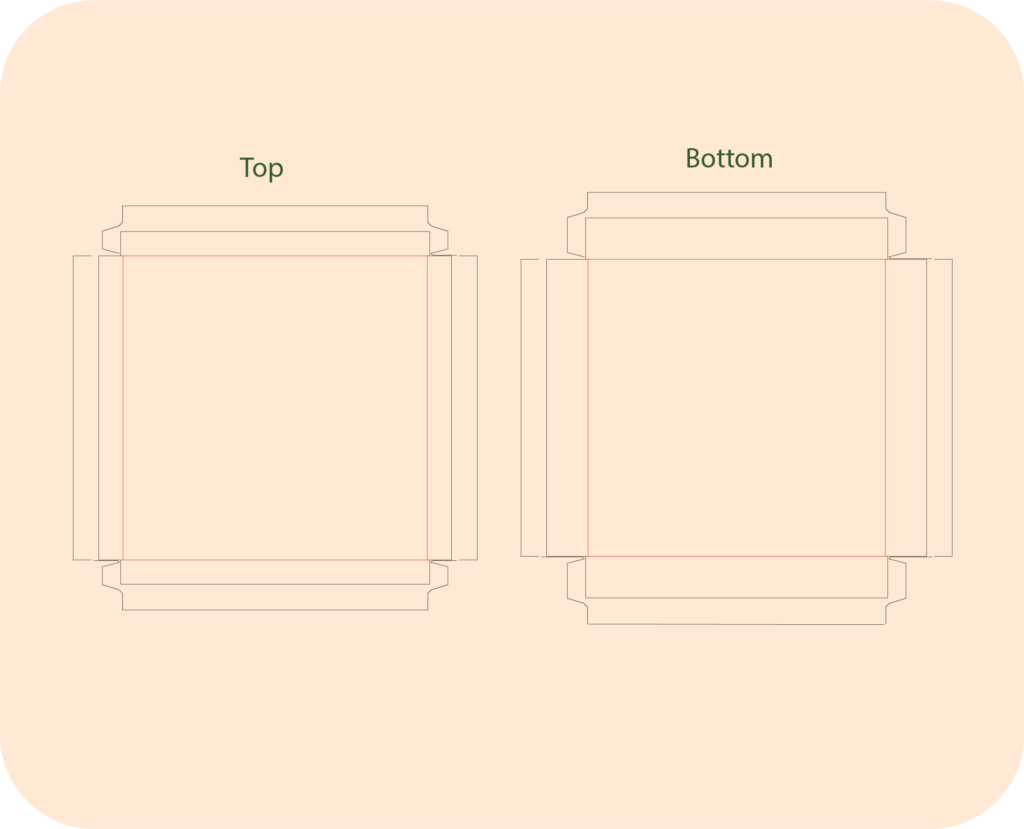

Which Design Files Need to Be Prepared (three commonly used box)

Tuck Top Box

Book Style Box

Top and Bottom Box

The Process Flow & Duration Estimation

Step 1: Free design (1day)

Join forces with our team for a day to craft a bespoke design that harmonizes seamlessly with your brand’s identity and vision.

Step 2: Free sampling (3-5 days)

We’ll deliver a tangible prototype of your custom CBD packaging box in 3-5 days , giving you the opportunity to evaluate its visual appeal, practicality, and craftsmanship

Step 3: Payment

Choose a payment method that fits your financial requirements from our range of flexible options.

Step 4: Production (5-15 days)

Within a timeframe of 5-15 days, our expert team carefully manages the production of your CBD packaging boxes, ensuring they adhere to our rigorous standards.

Step 5: Quality inspection (1-2 days)

Within 1-2 days, our quality control team meticulously inspects each box, underscoring our commitment to excellence.

Step 6: Delivery (3-30 days)

At last, your customized CBD packaging boxes are securely packaged and shipped within 3-30 days, with various shipping options to suit your needs.

Factors That Influence Prices of Custom CBD Packaging Box

How to Evaluate Quality Without Specialized Equipment

Custom CBD packaging boxes are commonly employed for a range of CBD products, serving to draw consumer attention and set the product apart from competitors.

Visual Check: Ensure smooth edges without tears, damages, or irregularities. Consistent appearance and color uniformity indicate quality.

Print Quality: Examine closely for clear and legible patterns and text on the box, there should be no blurriness or unclear areas.

Texture Assessment: Assess the box’s durability by applying gentle pressure to its sides and corners. It should maintain its shape without deforming or collapsing easily.

Foldability Test: Fold the edges and corners of the packaging box to check for tearing or cracking. A superior-quality box should demonstrate strong resistance to folding.

Odor Inspection: Smell the packaging for any unusual odors that could signal low-quality or environmentally unfriendly materials.

The Basic Knowledge About Custom CBD Packaging Boxes

We proactively research the most recent cannabis packaging requirements across different states, ensuring to furnish you with essential information. This empowers you to make informed and compliant decisions.

Enhancing Customer Engagement Through the E-Commerce Unboxing Experience

Lorem Ipsum is simply dummy text of the printing and typesetting…

Enhance Your Customers’ Experience with Custom Pre Roll Boxes

Lorem Ipsum is simply dummy text of the printing and typesetting…

What is Paperboard Packaging?

Lorem Ipsum is simply dummy text of the printing and typesetting…

What People SayAbout Our CBD Packaging Boxes

Ethan Davis

“I am thoroughly impressed with the durability of the CBD packaging boxes. They keep our products safe during transit and storage, ensuring that they reach our customers in perfect condition every time.”

Liam Wilson

“We’ve received numerous compliments from customers about the eco-friendly nature of our CBD packaging boxes. It’s great to know that we’re not only delivering quality products but also contributing to sustainability efforts.”

Ava Taylor

“The flexibility in sizes and customizable features of these paperboard boxes have revolutionized the way we meet the packaging requirements of my CBD business.”

Noah Martinez

“Our customers have been raving about the unique design of our CBD packaging boxes. They stand out on the shelves and attract attention, helping to drive sales and grow our business.”

The Common Pitfalls When Purchasing

A Brief Self-Nomination, Why Choose SYK?

SYK Productions, your ultimate packaging partner with over 20 years of industry-leading expertise, specializing in custom cannabis packaging for over a decade. We offer complete branding services, ensuring your brand stands out with quality, style, and efficiency. Choose SYK for optimal packaging solutions and elevate your brand.

Our competitive advantages are:

Direct Factory Benefits

Low Minimum Orders

Comprehensive Product Range

High Quality and Compliance

Swift Processing Times

24/7 Customer Support

Diverse Shipping Options

Secure Payment Methods

The FAQs About Custom CBD Packaging Boxes

SYK Productions offers a diverse range of packaging solutions tailored to your specific requirements. Our collection pages feature filters to facilitate your search.

We offer a minimum order quantity of 100 custom CBD packaging boxes, enabling small businesses and startups to establish their brand presence.

Our delivery service ranges from 7 to 30 days, with shipping methods tailored to your needs and timeframe.

Yes, expedited services are available upon confirmation from our production and shipping departments.

Yes, you can easily order samples for most packaging items directly from our website using the "Order Sample" button on each product page.