Custom Cannabis Mylar Bags Manufacturer

Custom branded mylar bags are essential in the cannabis industry, offering reliable packaging that preserves freshness and enhances product appeal. Our extensive range of custom cannabis bags is tailored to meet diverse packaging needs, offering a perfect blend of functionality, style, and protection to create the ideal solution for your cannabis products.

Outline for This Page

Each section is crafted for interactivity, enabling immediate access to related information with just one click.

What Custom Cannabis Mylar Bags Are

Cannabis bags, often called mylar bags, are flexible packaging solutions designed for storing and preserving cannabis products. Made from BOPET (Biaxially-oriented polyethylene terephthalate), these bags offer excellent barriers against oxygen, moisture, and light, extending the shelf life of their contents. They are also widely used in the food industry and other sectors.

Benefits of Custom Cannabis Mylar Bags

√ Superior Freshness: Blocks UV rays, moisture, and oxygen for extended shelf life.

√ Versatile Use: Suitable for flowers, edibles, and concentrates in various sizes.

√ Cost-Effective: Bulk savings and reduced product loss with durable materials.

√ Regulatory Compliance: Child-resistant, tamper-evident, and informative labels.

√ User Convenience: Resealable zippers and tear notches for easy access.

√ Retail Shelf Appeal: Custom design and glossy/matte finishes for eye-catching presentation.

What Can Cannabis Mylar Bags Be Used To Contain?

Cannabis Mylar bags are essential for cannabis packaging because they preserve product freshness, offer customizable options, and are cost-effective, making them a popular choice among consumers and businesses.

Hemp Flowers

Grinded Cannabis

Capsules and Pills

Pre-rolled Cones

Vape Cartridge

Edibles

CBD-Infused Toothpicks

CBD-Infused Drink

Hot Selling Types of Custom Cannabis Mylar Bags

Eco-friendliness of Custom Weed Jars

At SYK Productions, our custom cannabis mylar bags offer many eco-friendly options, such as biodegradable, recyclable, compostable, or hemp-based materials. These choices help businesses showcase their commitment to the environment while meeting consumer demand for greener products. By selecting these sustainable packaging options, cannabis brands can appeal to eco-conscious consumers and tap into a growing market that values environmental responsibility.

Expanding Customization Horizons of Custom Cannabis Mylar Bags

Bag Style:

Reversible Cap Vial

Pop Top Bottle

Translucent

Gusset Options for Mylar Bags:

Doyen (Round Bottom or Doypack): Ideal for products weighing less than 1 pound (0.45 kg).

K-Seal: Best for products weighing between 1 and 5 pounds (0.45 kg to 2.25 kg).

Corner Bottom (Plow Bottom or Folded Bottom): Suitable for products over 5 pounds (2.3 kg or more).

Bag Sizes

Our Standard Sizes:

Name

SIZE

CAPACITY

1 G Bag

3”x 4”

1 gram

1/8 oz Bag

3.5” x 5”

3.5 grams

1/4 oz Bag

4” x 6”

7 grams

1/2 oz Bag

5” x 8”

14 grams

1 oz Bag

6” x 9”

28 grams

1/4 Pound Bag

8” x 10”

4 ounces/ 112 grams

1/2 Pound Bag

10” x 12”

8 ounces/ 224 grams

1 Pound Bag

13” x 15”

16 ounces/ 448 grams

★ Custom Sizes Available

Additional Feature

Tear Notch:

Allows for easy opening.

Zipper Lock:

Child-resistant zippers are available.

Window:

Allows visibility of the contents inside.

Hang Hole:

Enables hanging on retail shelving.

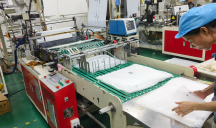

How Custom Cannabis Mylar Bags Are Made

Inside the Mylar Bag: Material Breakdown

Typically, cannabis mylar bags are made up of three layers:

Interior:Transparent PE

Surface:Printed Layer

Middle:Metalized Film

- PET (Polyethylene Terephthalate)

- BOPP (Biaxially-oriented Polypropylene) PET and BOPP are glossy but can be made matte. PET is favored for its better flexibility and quality

- MOPP (Monoaxially Oriented Polypropylene): MOPP has a matte finish and can be coated with a soft-touch layer

- VMPET: Vacuum Metalized Polyester Film (Commonly Used)

- Aluminum Foiling: Foil is easily damaged by pulling.

Which Design Files Need to Be Prepared

The Process Flow & Duration Estimation

Step 1: Free design (1day)

Work with our team for a day to create a custom design that matches your brand’s identity and vision.

Step 2: Free sampling (5-7 days)

We’ll provide samples of your custom mylar bags within 5-7 days for you to assess their appearance, functionality, and quality.

Step 3: Secure Payment

Choose the payment method from our flexible options that best fits your financial needs.

Step 4: Production (7-15 days)

Our skilled team will manage the production of your mylar bags over 7-15 days to ensure they meet our high standards.

Step 5: Quality inspection (1-2 days)

Each bag will be inspected within 1-2 days for quality and design accuracy, with any defects discarded.

Step 6: Delivery (3-30 days)

The finished products will be shipped within 3-30 days, with our shipping options and logistics ensuring the quality of the mylar bags is preserved.

Factors That Influence Prices of Custom Cannabis Mylar Bags

How to Evaluate Quality Without Specialized Equipment

Material Thickness: Check the bag’s thickness by feel. A good quality mylar bag should feel sturdy and not easily tear or puncture.

Seal Integrity: Inspect the heat seals along the edges. They should be uniform, strong, and without gaps or weak spots.

Clarity and Finish: Examine the bag’s clarity and surface finish. The printing should be clear, colors vibrant, and the finish (glossy or matte) should be even across the bag.

Odor and Moisture Resistance: Seal a strong-smelling item inside and check for leaks; test with moisture to ensure the bag stays dry.

Durability: Gently stretch and bend the bag to test its flexibility and durability. A high-quality bag should resist tearing or deforming.

Closure Mechanism: If the bag has a zipper or other closure, test it several times to ensure it works smoothly and consistently seals the bag securely.

The Basic Knowledge About Custom Cannabis Mylar Bags

Our blog features regular, in-depth articles on various aspects of custom cannabis mylar bags, aiming to give you valuable insights for making informed decisions.

How to Make Your Own Custom Cannabis Mylar Bags?

Lorem Ipsum is simply dummy text of the printing and typesetting…

Things to Know About Mylar Bags?

Lorem Ipsum is simply dummy text of the printing and typesetting…

Why Mylar Bags are the Best Food Storage Solution in 2024?

Lorem Ipsum is simply dummy text of the printing and typesetting…

What People Say About Our Custom Cannabis Mylar Bags

Liam Johnson

“I’m all about sustainability, and these bags have eco-friendly options that align with my values. They’re not only planet-friendly but also product-friendly. My cannabis edibles stay fresh for longer, and I couldn’t be happier.”

Alexander Smith

“These bags have added a touch of professionalism to our brand. They’re sleek, customizable, and secure. Our customers love the new look, and so do we. A great investment!”

Daniel Brown

“The convenience of these bags is unmatched. Easy to use, easy to reseal, and they keep my cannabis products in top condition. I appreciate the peace of mind these bags offer. Thanks for making my life easier!

Ryan Taylor

“The mylar bags from SYK Productions exceeded our expectations. The quality is unmatched, and the custom designs perfectly represent our brand.”

A Brief Self-Nomination, Why Choose SYK Productions?

SYK Productions is your premier choice for top-quality custom cannabis mylar bags. We specialize in compliance, a wide range of options, and tailored service, supporting brands from local producers to international names. Our focus is on efficient manufacturing and exceptional product presentation.

Our competitive advantages are:

Direct Factory Benefits

Low Minimum Orders

Comprehensive Product Range

High Quality and Compliance

Swift Processing Times

24/7 Customer Support

Diverse Shipping Options

Secure Payment Methods

The FAQs About Custom Cannabis Mylar Bags

Both bags and jars are excellent for storing flower, each with its benefits. While jars are ideal for display, they can be restricted in some states and are breakable. Mylar bags are more durable, available in opaque or clear options, and also customizable with compliance features.

3.5 gram Mylar bags for flower are by far the most popular in our collection - 3.5 grams (an 8th) is the most popular weed purchase across the board. Our 7, 14, and 28 gram bags are also popular, but not as popular as the 3.5s.

Yes, Cannabis Mylar bags offer protection against UV light, which can degrade the quality of many products over time. This makes them ideal for storing light-sensitive items like cannabis and certain foods.

A properly sealed Cannabis Mylar bag will have a flat, smooth seal with no gaps or wrinkles. You can test the seal by pressing gently on the bag; if no air escapes, the seal is secure.

Yes, we offer customization options for Cannabis Mylar bags. You can add your brand’s logo, choose different colors, and select various sizes to create a unique and branded packaging solution for your products.