Custom Cannabis Packaging Bottles Manufacturer

Cannabis packaging bottles are essential for preserving product quality and enhancing your brand’s presence in the competitive cannabis market. At SYK Productions, we offer a wide selection of premium wholesale bottles and custom solutions to elevate your product presentation and support your business growth. Our bottles are fully customizable, ensuring compliance and maximizing shelf appeal.

Outline for This Page

Each section is crafted for interactivity, enabling immediate access to related information with just one click.

What Cannabis Packaging Bottles Are

Cannabis packaging bottles are containers designed to protect cannabis products like oils and tinctures. They ensure product quality and safety with features like child-resistant caps and UV protection. These bottles also serve as a branding tool, with customizable options to enhance your brand’s appeal.

√ Light Protection: Shield contents from light and UV radiation, preserving liquid potency.

√ Precise Dosing: Droppers ensure exact and consistent measurement.

√ Portability: Compact design makes them easy to carry and daily use.

√ Durability: Sturdy glass resists chemical interactions, keeping contents pure.

√ Recyclable: The bottles can be reused multiple times, helping to reduce costs.

√ Versatility: Suitable for various products like herbal tinctures, CBD oils and Edibles.

Hot Selling Types of Cannabis Packaging Bottles

Custom CBD packaging boxes are commonly employed for a range of CBD products, serving to draw consumer attention and set the product apart from competitors.

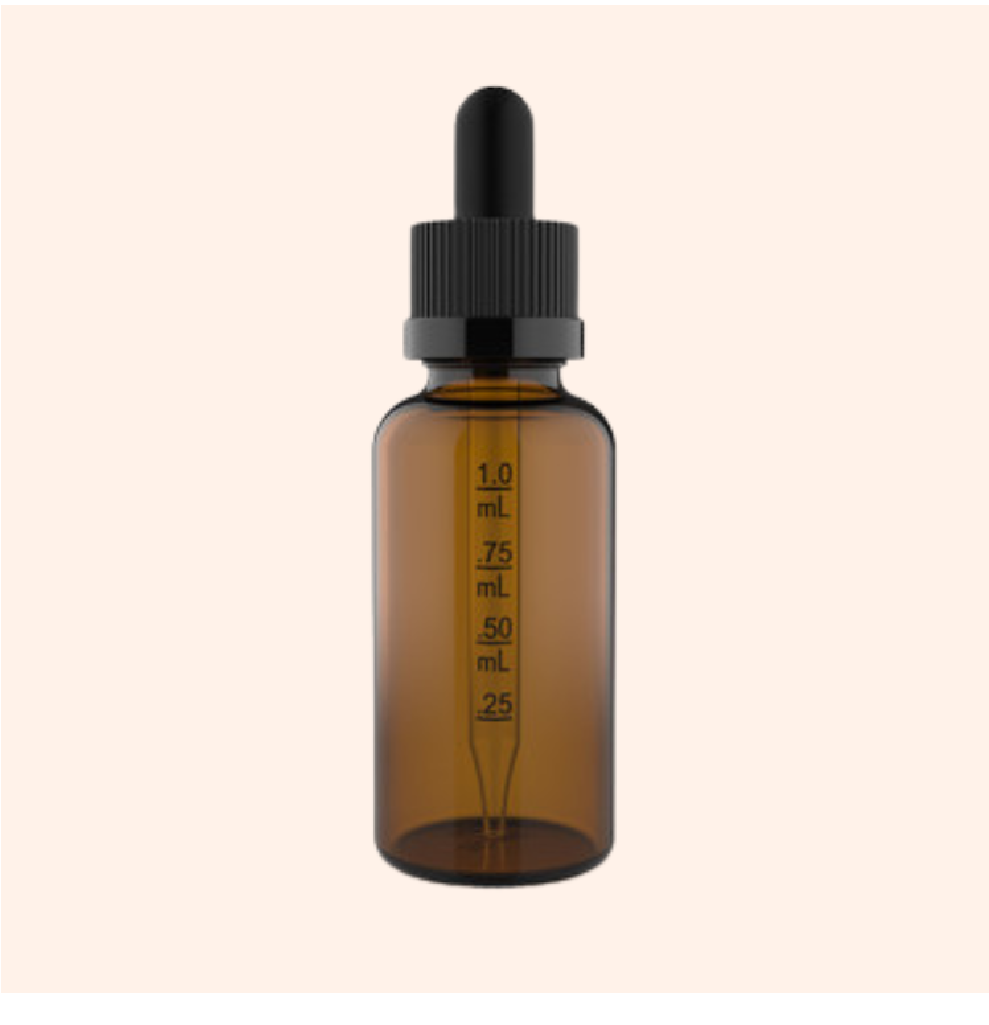

Dropper Bottle

Graduated Dropper Bottle

Rectangular Tincture Bottle

Reversible Cap Vial

Opaque Pop Top Bottle

Tamper Evident Pop Top Bottle

Pop Box Pop Top Bottle

Plastic Syrup Bottle

Eco-friendliness of Custom Cannabis Packaging Bottles

At SYK Productions, our custom cannabis packaging bottles are made from durable, eco-friendly materials such as glass and sustainable plastics. Glass is fully recyclable and ideal for sustainable packaging, while our plastics are designed to minimize environmental impact. The sturdy design of our bottles ensure they last and can be reused, reducing waste. Choosing our packaging bottles mean supporting environmental health while benefiting from a reliable and reusable product.

Expanding Customization Horizons of Custom Cannabis Packaging Bottles

Standard Dropper Bottle Sizes and Labels

Capacity

Suitable Label Sizes

0.5 oz

15 ML

1 oz

30 ML

2 oz

30 ML

1.25” x 2.50” Rectangle

1.25” x 2.50” Rectangle

1.25” x 2.50” Rectangle

1.25” x 2.50” Rectangle

1.25” x 2.50” Rectangle

1.25” x 2.50” Rectangle

1.25” x 2.50” Rectangle

1.25” x 2.50” Rectangle

1.25” x 2.50” Rectangle

★ Custom Cones & Filter Sizes Available

Reference Picture

Color

For Plastic Bottles

For Glass Dropper Bottle

Reversible Cap Vial

Pop Top Bottle

Translucent

Opaque

Branding Options

Custom Printing

Custom Bottle Label

Printing Design File Requirements

Additional Feature

Tamper Evident Collar

Tamper Evident Seal

Tamper Evident Shrink Band

Child-Resistant Cap

How Custom Cannabis Packaging Bottles Are Made

The Process Flow & Duration Estimation

Step 1: Free sampling (3-5 days)

We will deliver similar samples bottles within 3-5 days, allowing you to assess their material, functionality, and quality craftsmanship.

Step 2: Payment

Choose a flexible payment option that suits your financial needs.

Step 3: Mold Creation(7-10 days)

We create custom molds based on your approved design, capturing every detail accurately.

Step 4: Production (7-15 days)

Over a period of 7-15 days, our skilled team produces your custom weed jars, ensuring they meet high standards.

Step 5: Quality inspection (1-2 days)

Within 1-2 days, each jar is inspected for consistency and quality. Defective jars are discarded.

Step 6: Delivery (5-30 days)

Finished products are shipped within 5-30 days, with efficient logistics ensuring quality preservation during transit.

Factors That Influence Prices of Custom Pre-Rolled Cones

How to Evaluate Quality Without Specialized Equipment

Visual Inspection

Check for any visible defects, such as cracks, bubbles, or uneven surfaces. Ensure the print quality is clear and accurate.

Fit and Seal

Test how well the lid or cap fits. It should seal tightly without gaps, ensuring the contents are secure.

Ease of Use

Evaluate how easy it is to open and close the bottle. It should operate smoothly without excessive force.

Lid Type and Seal

The type of lid (screw-top, snap-on, etc.) and seal quality (airtight, child-resistant, etc.) affect cost, with child-resistant and airtight lids being more expensive.

Design Costs

Initial design and development costs, including mold creation for unique shapes or sizes, can influence the final price. Custom molds or dies are often costly.

The Basic Knowledge About Custom Cannabis Packaging Bottles

On our blog, we regularly share in-depth articles covering various aspects of custom cannabis packaging bottles, offering valuable insights to help you make informed decisions.

Dropper Bottle Label Size Guide

Lorem Ipsum is simply dummy text of the printing and typesetting…

Steps for Properly Cleaning Glass Bottles for Reuse

Lorem Ipsum is simply dummy text of the printing and typesetting…

The benefits of using reversible cap vials

Lorem Ipsum is simply dummy text of the printing and typesetting…

What People Say About Our Custom Cannabis Packaging Bottles

Sarah Thompson

“I’ve been using their bottles for my cannabis business, and I’m thoroughly satisfied with the quality and functionality. Whether it’s glass dropper bottles or pop top bottles, they’ve got me covered.”

Emily Roberts

“Their vials have made a significant difference in my product packaging. Customers appreciate the convenience of the reversible cap, and I appreciate the child-resistant feature. It’s a win-win!”

Jason Miller

“Having the flexibility to customize every detail has been a game-changer for us. These bottles perfectly reflect the premium nature of our products, and our customers have noticed!”

Mark Davis

“We love the child-resistant caps—they’re easy for adults to open but ensure the safety of our customers’ families. Plus, the custom designs really help us stand out on the shelf.”

The Common Pitfalls When Purchasing

A Brief Self-Nomination, Why Choose SYK Productions?

With over a decade of experience, SYK Productions creates premium custom cannabis packaging bottles designed to elevate your brand. Our bottles offer the perfect combination of style and protection, ensuring your products stand out while meeting industry standards. Trust SYK Productions for reliable, high-quality packaging solutions.

Our competitive advantages are:

Direct Factory Benefits

Low Minimum Orders

Comprehensive Product Range

High Quality and Compliance

Swift Processing Times

24/7 Customer Support

Diverse Shipping Options

Secure Payment Methods

The FAQs About Custom Cannabis Packaging Bottles

The choice between child-resistant and easy-open caps depends on your specific product and local regulations. Child-resistant caps are recommended for products that require enhanced safety measures, while easy-open caps are suitable for products meant for adult use. Be sure to check your local laws and requirements.

Child-resistant packaging undergoes rigorous testing and certification processes conducted by the ASTM (American Society for Testing and Materials) and CPSC (Consumer Product Safety Commission). To be deemed child-resistant, the packaging must be designed to be significantly challenging for children under the age of five to open within a reasonable timeframe, while remaining usable for normal adults. This definition is derived from the Poison Prevention Packaging Act (PPPA) established in 1970. Testing takes place in controlled environments where young children attempt to open the containers.

Yes, many of our pop top bottles can be customized with your branding, labels, and logos. Customization options are available to help you create a unique and recognizable look for your cannabis products.

Yes, glass dropper bottles are an ideal choice for packaging CBD oils and other cannabis liquids. Their glass construction prevents contamination and ensures precise dispensing of the product.

Our pop top bottles offer a high level of protection and discretion for customers; however, they may not completely eliminate all odor transfer. To enhance odor control, many customers choose to pair our pop top containers with mylar exit bags, which are indeed odor-proof. Mylar bags are a popular choice because they can be reused multiple times. Customers can purchase pop tops from your shop, place them inside their mylar bag, and enjoy the added benefit of containing the distinctive cannabis scent.